In the realm of modern materials, PP Sheet Exporters in Gujarat have emerged as versatile solutions for a myriad of applications. From packaging to construction, these sheets offer durability, flexibility, and cost-effectiveness. In this comprehensive guide, we delve into the world of PP sheets, exploring their uses, benefits, and frequently asked questions.

What are PP Sheets?

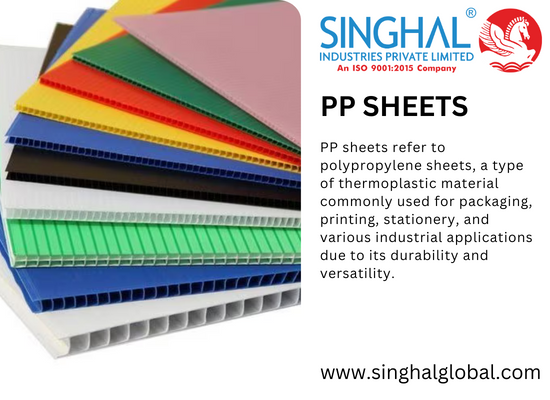

P P Sheets Manufacturer in Gujarat are made from polypropylene, a thermoplastic polymer known for its exceptional properties. These sheets are manufactured through a process of extrusion, where molten polypropylene is formed into thin, flat sheets. PP sheets come in various thicknesses, colors, and textures, catering to diverse requirements across industries.

Uses of PP Sheets:

Packaging: PP Sheets Suppliers in India are widely used in packaging applications due to their lightweight nature and high impact resistance. They are commonly employed in industries such as food and beverage, pharmaceuticals, and electronics for creating boxes, trays, and containers.

Graphic Arts: In the realm of graphic arts, PP sheets serve as an ideal substrate for printing applications. Their smooth surface allows for vibrant and crisp printing, making them suitable for signage, banners, and promotional materials.

Construction: PP sheets find applications in the construction industry for creating temporary barriers, formwork, and protective coverings. Their weather-resistant properties make them ideal for outdoor usage, providing durability and longevity.

Stationery: PP Sheet Exporters in Gujarat are popularly used in stationery products such as binders, folders, and document sleeves due to their tear-resistant and water-resistant properties. They offer protection to important documents while maintaining a professional appearance.

Automotive: Within the automotive sector, PP sheets are utilized for interior trim components, such as door panels, dashboard covers, and trunk liners. Their ability to withstand harsh conditions and retain structural integrity makes them a preferred choice for automotive applications.

Benefits of PP Sheets:

Durability: P P Sheets Manufacturer in Gujarat exhibit excellent durability, resisting impact, tearing, and abrasion. This durability ensures longevity in various applications, reducing the need for frequent replacements.

Flexibility: Despite being robust, PP Sheets Suppliers in India are inherently flexible, allowing for easy fabrication and forming into desired shapes. This flexibility enhances their usability across diverse industries.

Chemical Resistance: Polypropylene is inherently resistant to many chemicals, including acids, alkalis, and solvents. This chemical resistance makes PP Sheet Exporters in Gujarat suitable for applications where exposure to harsh substances is a concern.

Recyclability: PP sheets are fully recyclable, contributing to sustainability efforts in industries where environmental responsibility is paramount. They can be easily processed and reused in the manufacturing of new products, reducing waste and conserving resources.

Cost-Effectiveness: Compared to alternative materials such as PVC or acrylic, PP sheets offer a cost-effective solution without compromising on performance. Their affordability makes them an attractive choice for budget-conscious projects.

Conclusion:

Polypropylene (PP) sheets stand as versatile solutions across a multitude of industries, offering durability, flexibility, and cost-effectiveness. From packaging to construction, graphic arts to automotive applications, the versatility of PP sheets knows no bounds. With their myriad benefits and recyclability, they exemplify modern material innovation while catering to the diverse needs of businesses and consumers alike. Embrace the potential of PP sheets and unlock a world of possibilities in your projects and applications.

Frequently Asked Questions (FAQs):

Q1: Are PP sheets suitable for outdoor use?

A1: Yes, PP Sheets Suppliers in India are suitable for outdoor use due to their weather-resistant properties. They can withstand exposure to sunlight, moisture, and temperature fluctuations without degrading or losing their structural integrity.

Q2: Can PP sheets be recycled?

A2: Absolutely! PP sheets are fully recyclable. After use, they can be collected, processed, and reformed into new products, contributing to a circular economy and reducing environmental impact.

Q3: Are PP sheets food-safe?

A3: Yes, PP sheets are considered food-safe and are commonly used in food packaging applications. They comply with regulatory standards for contact with food and provide a hygienic solution for storing and transporting food products.

Q4: How do I clean PP sheets?

A4: Cleaning PP sheets is straightforward. Simply use a mild detergent solution and a soft cloth or sponge to wipe the surface. Avoid abrasive cleaners or scouring pads, as they may scratch the material.

Q5: Can PP sheets be customized?

A5: Yes, PP sheets can be customized to meet specific requirements. They are available in various colors, thicknesses, and textures, and can also be tailored in terms of size and shape through cutting or thermoforming processes.